Free Shipping Within USA | 1-year Warranty

What You Need to Know About Mini Excavator Auger Attachment

Mini excavators are highly effective and versatile in the construction and landscaping industries, especially when equipped with the right attachments. A mini excavator auger attachment is one of the most vital and useful attachments to have as it is designed to enhance the operational efficiency of your projects. It can turn a basic mini excavator into a powerful drilling machine, capable of handling a variety of soil conditions and drilling tasks with precision and speed. This guide will delve into everything you need to know about mini excavator auger attachments, from their basic functions to tips on selection and maintenance.

What is a Mini Excavator Auger Attachment?

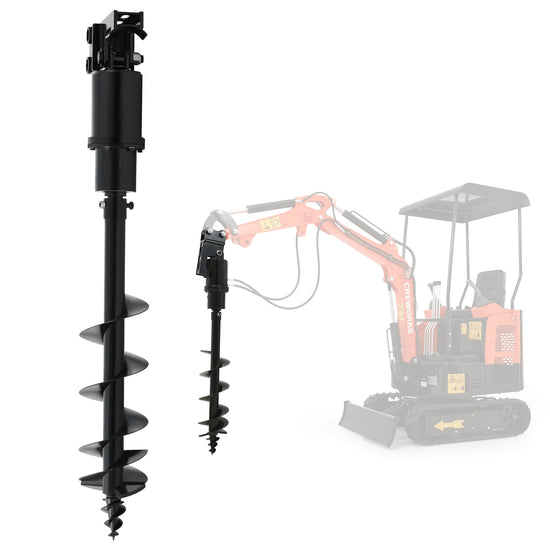

An auger attachment for a mini excavator can transform a standard mini excavator into a versatile drilling machine. This attachment mainly comprises four components:

Drive Unit: This is the heart of the auger system, converting hydraulic power from the excavator into rotation and horque necessary for drilling.

Auger Bit: Attached to the drive unit, the auger bit does the actual drilling and is available in various sizes and styles to suit different ground conditions.

Hoses: These supply hydraulic fluid to the drive unit, powering the system.

Mount: This secures the auger system to the excavator, providing stability and support during operation.

Operating an auger attachment for mini excavators requires a two-way auxiliary hydraulic system. If your excavator is not already equipped with this system, modifications may be necessary. These should be made in consultation with the equipment manufacturer to ensure compatibility and safety.

What Can You Benefit From a Mini Excavator Auger Attachment?

Incorporating an auger attachment into your mini excavator setup brings many compelling benefits:

Increased Efficiency: The primary advantage of using an auger attachment for a mini excavator is the substantial increase in efficiency. This tool allows for rapid, precise drilling, dramatically speeding up project timelines compared to traditional manual digging methods.

Versatility: One auger attachment for a mini excavator can serve multiple purposes, thanks to the variety of auger bits available. These bits are easily interchangeable, enabling operators to switch from one job to another effortlessly.

- Accessibility In Tight Spaces: Mini excavators fitted with auger attachments can access and operate in areas that are too restrictive for larger machinery. This ability is invaluable in urban and residential settings where operational space may be limited and precision is essential. The compact size of mini excavators, combined with the directional agility of auger attachments, allows for drilling in corners and confined spaces without compromising performance.

Reduced Physical Strain and Enhanced Safety: Augers provide a stable and secure method of performing drilling tasks, as operators can remain in the comfort and safety of the machine’s cabin while finishing their drilling work. This stability greatly reduces the risk of accidents commonly associated with manual digging, such as cave-ins or tool slippage. Additionally, since the work is mechanized, physical strain on workers minimizes the risk of strain-related injuries.

What Are the Types of Auger Bits?

As auger bits, a main component of auger attachment, come in various types that can influence drilling tasks, understanding these types of auger bits is crucial to choosing your ideal auger attachment. The following are four common types of auger bits:

Light-Duty Auger Bits: Ideal for soft, unobstructed soils, these augers are equipped with bolt-on teeth and are Hest suited for light work such as organic soil drilling or shallow depths.

Heavy-Duty Auger Bits: Built to tackle tougher terrains such as clay and fracturable rock, heavy-duty auger bits feature robust cast heads with drive-in teeth. These auger bits are designed to withstand the stresses of hard ground drilling, providing durability and reliability under challenging conditions.

Tree Auger bits: Specifically designed for landscaping and forestry applications, tree auger bits feature a unique two-diameter design. This allows for the creation of a tapered hole, which is wider at the top, providing a suitable planting environment that encourages root growth and stability for newly planted trees.

Rock Auger Bits: Engineered for the toughest drilling tasks, rock augers can penetrate solid rock, concrete, and other hard materials. They are equipped with specially designed teeth strong enough to handle the hardest substrates, making them essential for construction projects that involve substantial ground excavation.

How to Choose the Right Auger Attachment for Your Mini Excavator?

Selecting the right auger attachment for a mini excavator is critical to maximizing efficiency and effectiveness. Here are some main factors that can help you choose the best auger attachment for your needs:

- Match Specifications with Excavator Capabilities: It is essential to align the auger’s hydraulic flow and pressure requirements with your mini excavator’s specifications. This ensures the auger attachment operates efficiently without overloading the mini excavator’s hydraulic system.

Select the Right Auger Bit: Your choice of auger type should be guided by the depth and diameter of the holes you plan to drill, and the ground conditions under which the drilling is to be done. For example, light-duty auger bits are suitable for softer soils, while heavy-duty auger bits are needed for harder substrates. Besides, make sure the auger bit is compatible with the auger drive in size and power.

Consider the Mounting System: Auger attachments also come with different mounting options that can affect their ease of attachment and flexibility in use. Choose a system that is easy to attach and compatible with your mini excavator.

Assess Operational Needs: Consider the typical working conditions and the purpose of your projects. This will help you decide if you need an auger attachment that can handle varied tasks, or if a specialized type would be enough.

There are all kinds of auger attachments on the market. If you are currently looking for a high-quality 8″ Diameter 45″ Depth auger attachment now, AHM’s hydraulic auger drill attachment for mini excavator can be a good choice for you. This robust auger attachment is ideal for a wide range of applications, including installing fence posts, laying foundations, planting trees, and conducting soil sampling. Designed to fit mini excavators up to 2 tons, it boasts an impressive 8-inch diameter and can drill down to a depth of 45 inches. With a hydraulic flow rate of 8-16 gpm and a speed of 40-82 rpm, it ensures quick and effective drilling in various soil conditions.

Hydraulic Auger Drill Attachment for Mini Excavator 8″ Diameter 45″ Depth

$799.00

How to Maintain Your Auger Attachment for Mini Excavators?

After you get your best mini excavator auger attachment, proper maintenance is important for extending its life and ensuring it performs optimally. Here are some tips to keep your auger attachment in top condition:

Regular Inspections: Check your auger attachment regularly for wear and damage. Look for bent or broken teethand cracks in the auger flight. If the teeth can be safely straightened without compromising their strength, you can use appropriate tools to realign them. If the teeth have experienced significant stress or repeated bending, a replacement might be necessary.

Rust Prevention and Routine Lubrication: Regularly oil your auger to prevent rust, especially before storing it for extended periods. Moreover, keep the moving parts of the auger attachment well-lubricated to reduce friction and prevent wear.

Follow Manufacturer’s Guidelines: Adhere to the manufacturer’s recommended maintenance schedule and practices. Use only approved parts and fluids for repairs and maintenance.

In summary, choosing and maintaining the right mini excavator auger attachment can significantly enhance your mini excavator’s utility, making it a powerhouse for drilling projects. By selecting the appropriate auger attachment, operators can enjoy increased productivity, reduced downtime, and prolonged equipment life. If you’re looking to expand the capabilities of your mini excavator, consider investing in a high-quality auger attachment that meets your specific operational needs.