Free Shipping Within USA | 1-year Warranty

USA Excavator: Unearthing the Nation’s Infrastructure

USA Excavator are the foremost champions of the construction and infrastructure sectors with their one-of-a-kind and multiple uses which are instrumental in the development and maintenance of both urban and rural environments.

These heavy trucks are basically designed for digging, lifting, and moving earth and materials, which make them necessary for such works as site preparation, trenching, and demolition.

Their various kinds of work, which are also supported by different attachments such as buckets, hammers, and grapples, they may not be limited to the mere excavation only.

For example, in case of road construction, the work of an excavator is to dig the foundations of bridges and overpasses so that these structures may be built on solid ground.

Besides, the scope of excavators is nearly as large in the device of the existing infrastructure and upkeep. The thorough maintenance of roads, bridges, and other utilities puts a heavy load on technical groups who have to cut the ground to access the underground systems for the necessary repairs or upgrades.

In crowded urban areas with limited space and closely packed existing structures, excavators with their agile movement can get into tight spots and do their job while lessening the disturbance caused by the work.

Their role is quite significant in cities in particular, where the old infrastructure requires taking care of at all times so as not to get into trouble and cause danger or service interruption.

The performance of excavators in these different situations proves that they are highly necessary not only for the building of new projects but also the sustainment of the already existing ones.

Key Takeaways

- Excavators are essential machines that through their operations, for example, digging, lifting, and moving materials, make it possible to build and maintain the infrastructure related to foundations, trenches, and other necessary structures.

- Excavators allow building of highways, bridges, domestic and commercial properties, etc., that are the basic infrastructure of the economy and development, the impact thus of excavators on the economy and development is large-scale and vital.

- The changes of the excavator technology in the USA have led to the designing of the machines that are more efficient, have more application, and are less harmful to the environment, which makes the work done faster and with less emission of greenhouse gases.

- The issues of safety and regulations in relation to the use of the excavator have always been a serious problem to the public not only the workers in the industry. The imposition of strict safety standards along with the implementation of regulations is an effort to prevent such accidents and sustain the safety of workers and the public.

- Case studies present the indispensable function of the excavators in the great infrastructure undertakings. So, the idea about the flexibility and effectiveness of the heavy machinery in doing complex works of the construction is depicted through these examples.

- The future of excavators in the USA comes with the excitement of trends and innovations that include high-tech integration, automation, and sustainable practices with the primary aims of reducing emissions and energy consumption besides improving product characteristics.

- Excavation and infrastructure development are responsible for environmental issues that are raising in number and various in type. Therefore, there is a notable move towards sustainable practices and the adoption of relevant technologies to minimize the damage caused to the ecosystem.

- Indeed, excavators are one of the main contributors to disaster management besides disaster response and recovery teams since they have the ability to remove heavy debris, get people who are trapped under collapsed buildings, and rebuild the flooring of the disaster area to foster the process of recovery.

The economic consequences of excavators are, however, not limited to their handy utility on the site of a construction only.

By opening up solidly and thoroughly the way for the civilization, sanitizing the road for the passage of people, critics, and investors, the machines have become indomitable actors to the creation of wealth.

The construction branch is the main source of employment in the USA, and in many projects, excavators are at the center of the drive that makes this branch upward.

For instance, big infrastructures like highways, airports, or public transit systems are increasingly depending on the use of heavy excavating equipment to carry out excavation work that will provide the base for these kinds of services.

As the advancement of these works continues, the number of jobs created increases, and it is not only operators and laborers who come to mind, but also engineers, architects, and suppliers.

Besides that, the correlation between economic growth and the presence of strong infrastructure is positive and quite obvious. An efficient transportation network means less time and lower costs for businesses travelling to their customers, which directly translates to increased productivity and competitiveness.

In some regions there is a pattern of increased commercial activities and investment after the utilization of excavators in the improvement of infrastructure.

So, the development of the highway could be a great idea of the urban areas of the future that lead to new businesses being created in that region and thus, the local economy is booming by these ripple effects.

The fact that-a-as-are tools to speed up these developments makes them one of the main economic strategies at homes and country levels.

The Evolution of Excavator Technology in the USA Excavator

The progression of USA excavator technology in the U.S. is a major storyline with its litany of milestones that had a transformative effect on how these machines function. The change in their operation from when they were simple steam-powered contraptions in the early 20th century to today’s high-end hydraulic systems is nothing short of a miracle.

One of the most important turning points in the history of the excavator led to the emergence of hydraulic machinery in the 1950s era. It was a breakthrough that essentially made the operators’ jobs more complex but simple at the same time. For example by digging deeper trenches or lifting heavier loads they could accomplish their goal faster than before.

Almost all the recent developments in the field have been directed towards the goal of increasing the overall excavator capability. By the means of computer systems and automation, smart excavators with GPS and telematics have been developed. As a result of these developments, more effective use of time and reduced costs are attainable since real-time monitoring of the situation is possible.

In the recent past, various technological advancements have contributed greatly to the improvement of the excavator’s capabilities. By incorporating automated cutting-edge computing systems, smart machines were created, which were further equipped with GPS and telemetric technologies.

One of the changes in this trend resulted in an inclination of excavators towards environmental benefits. As a result of fuel-saving attempts and tighter emissions control, most of the machinery utilized in construction industries in the United States are now in line with global warming-mitigation targets.

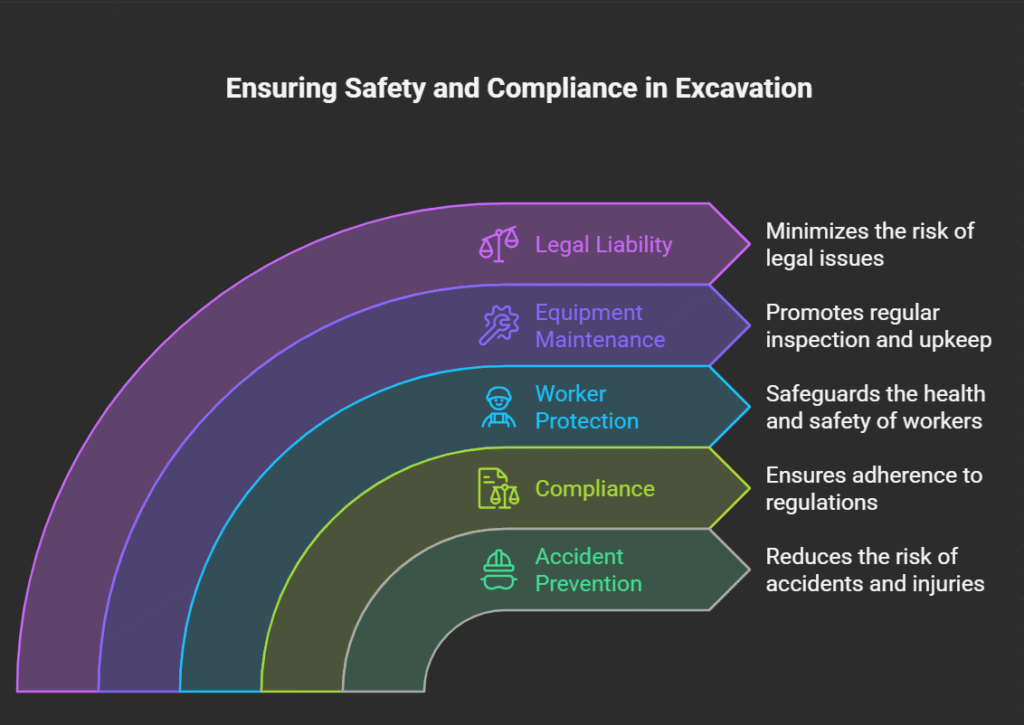

The Importance of Excavator Safety and Regulations

Without any doubt, safety is of utmost importance during the operation of excavators, a heavy machine that can inflict massive damage if not handled carefully. Moreover, operators must not only be trained in equipment operation but also in spotting the risks and eliminating them while at the site.

Some of the most common safety concerns in this line of work are tipping hazards, falling objects, and underground strikes of utilities. Organizations such as OSHA (Occupational Safety and Health Administration) have laid out tight rules about excavator operation and safety standards to take care of these issues.

By following the rules of the game, safety regulations ensure the well-being of workers and a significant decrease in accidents. For instance, before starting their routine performance, operators must perform checks to make sure that they have all the safety features working well.

Also, the ways of learning involve the use of training programs which among other things, instill in the workers the value of alertness and the importance of good communication in the prevention of accidents during work on excavation.

Through the observance of these rules and forging a strong safety culture at the scene of work, firms can lower the number of events that cause injuries and death related to the activities of the excavators to a great extent.

Case Studies: Excavators in Major Infrastructure Projects

Case studies raise the curtain on the essential role of the USA-based excavator machines in the federal-level infrastructural projects, which are spread all over the country, e.g.,

One of the most prominent instances is the Big Dig construction in Boston, Massachusetts, i.e., a gigantic endeavor aiming at taking the Central Artery underground, relieving the city of traffic congestion caused by it.

While excavators dug deep trenches for highway tunnels, they also handled the complicated logistics of existing utilities and structures above the ground. The whole process has not only demonstrated the power of excavators but also their dependence on accurate planning and deployment in the heart of the cities.

The biggest example of the present-day infrastructure projects is a study on the LAX (Los Angeles International Airport) expansion. In order to cope with the growing number of flights, LAX renovations were extensive, as it is one of the busiest airports globally.

Among other tasks, the excavators were engaged in the preparation of the new terminals and runways. A large amount of earth was moved to make room for the new infrastructure, and at the same time, operations at the airport continued uninterrupted.

So, in short, these real-life instances not only reflect excavators as tools but even more as machines without whom large-scale infrastructural projects would have never gotten off the ground.

The Future of Excavators in the USA: Trends and Innovations

If we talk about the future in terms of today’s technologies, numerous trends are shaping the future of excavators in the USA. One of these is the substantial inclination toward automation and the use of robots in the field of excavation.

The gradual development of technology will suggest to us the presence of more machines with limited human intervention in the field of excavation. A major factor in raising productivity is the ability of these machines to operate 24/7 without taking a break as well as the reduction of labor costs which goes along with it.

Moreover, the issue of environmental friendliness appeared ever more important among construction companies bearing in mind which way the market for “green” goods is heading. Manufacturers have been pushed in recent years to launch greener excavators with alternative fuel or hybrid technology use. These products do not only aim at emitting less and reducing the environmental impact but also at keeping quality unwavering.

On top of that, the precision of data collection is enabling the use of devices such as sensor-equipped excavator loaders that can alert operators to help them avoid breakages via predictive maintenance interventions well before the time of actual breakdowns.

As these trends progressively solidify their positions within the deep crevices of the industry, one will have to look out for how they will reshape the constructs of the business such as methods of integration all over America.

The Environmental Impact of Excavation and Infrastructure Development

Although excavators form the backbone of infrastructure development, their application raises several environmental concerns that cannot be ignored. The most common effects of land excavation are erosion, habitat destruction, and the interruption of the local ecosystems which can even lead to extinction of some species of plants or animals if the soil is not managed well.

Besides that, massive digging projects can reshape the area and rivers, resulting in the rarest of animals losing their habitats and water getting polluted.

So, it becomes mandatory for these companies that deal with different constructions to not only care about their profits but at the same time, make sure that they are implementing the most environmentally responsible behaviors during the digging process.

First and foremost, companies are turning to the green side of the shovel marked by their commitment to sustainable excavation methods like this one that has the main feature of using gradual erosion control surfaces contaminated with silt causing particulates like sand or small gravel to trap and hold the contaminants securely there.

Moreover, such a practice may become a leading concept behind the idea of mandatory EIA as an initial phase for the project implementation period to pinpoint the type of harm capable of occurring in the ecosphere and to come up with a preventive measure, thus minimizing loss or damage.

This sector merely by being committed to the cause may be able to provide an ideal balance between the two – Infrastructure development along with Preservation.

The Role of Excavators in Disaster Response and Recovery

Aside from the various uses mentioned above, the presence of dismantlers is quite imperative in the setup of relief and recovery operations after calamities like tsunami, earth tremors, or floods.

In the latter scenarios, the emergency should be of such nature that it becomes necessary to cut it as soon as possible to remove the debris that block the roads, enable the access to the arrested areas, and even facilitate the activities of rescue and relief at the exposed sites.

One is required to take the opposite position of an excavator which is the very first thing that happens at the scene and the closest spots to the victim areas that remove the barriers in the rescue efforts, such as uprooted trees and other debris along with buildings that have lost their structural element support thus making it impossible to move freely there.

To explain this in another way, after Hurricane Katrina leveled New Orleans in 2005, the first thing that emergency crews did through the power of the heavy machinery was to clear debris from the streets and neighborhoods as a way to open the routes to those in need of immediate help.

On a similar note, during the consecutive phases of earthquake recovery in California, the method via which dismantlers were performing the safe removal of ruins from already demolished structures was simultaneously allowing the competent teams of search and rescue to continue their work properly and efficiently.

The capacity of these heavy-duty machines to be swiftly called into action and undertake the essential tasks is the core of their exceptional value not only in building industries but also in humanitarian operations during distressing times.