Free Shipping Within USA | 1-year Warranty

Road Rollers – Essential Machines for Smooth and Durable Surfaces

Introduction to Road Rollers

The smoothness and durability of every road that is well constructed are, in part, the results of the use of a road roller. Another term used for a compactor is also a compactor, this amazing machine, which consolidates, compacts, and stabilizes loose soils, gravels, asphalt, and other construction materials, basically, unites the materials for the construction of roads and other infrastructure to be used in the future.

Road rollers’ history is a case from the 19th century, when they were powered by horses and steam, and rollers were used to compact soil and gravel. The development of diesel-powered, vibratory, and smart rollers came after the gradual change of horse-drawn and steam rollers.

Nowadays, road roller machines are necessary for infrastructure development. Building a small driveway, or a six-lane highway, the concept is the same, you will need a road roller to make sure that your foundation is stable and will not get cracked or eroded by time.

Moreover, road roller machines are the ones that give “roads their backbone” — without them, asphalt would get crushed and loose soil layers would get loosened. Along with the compaction function that they have, the machines are also combining the particles in a way that they become inseparable, thus stability and holding force are achieved.

How Road Rollers Work

To get an idea about how a road roller does its job, one could think of a situation where wet sand is being compressed by one’s foot – the more the pressure the denser and smoother the sand becomes. Road rollers are using the very same technique but the force is enormous because the job is done by heavy drums and sometimes helped by vibrations.

A roller can do the compaction mainly through two methods:

- Static compaction – The main weight of the roller presses the surface to the bottom, thereby extracting the air from the surface and bringing the material particles closer together.

- Dynamic compaction – The oscillating drums of vibratory rollers produce rapid impacts that more efficiently rearrange particles, thus achieving greater depths of compaction.

The operator adjusts the speed, frequency of vibrations, and direction of the roller, which guarantees that the pressure will be evenly distributed. Typically, operators use the multiple pass method to asphalt works, as they come first with the edges and then move towards the center to prevent the formation of cracks.

Lots of these vehicles today are fitted with on-board sensors and compaction meters, enabling the density to be measured in real-time. This accuracy tightens the margin for errors and ensures high-quality standards throughout the entire project.

Major Types of Road Rollers

The designs of road rollers could be variable for different compaction requirements. Here are the primary ones used in contemporary construction.

Smooth Wheeled Rollers

They are also known as tandem or static rollers and are the most common types. There are usually one big drum at the front and one or two wheels at the back.

- These rollers are best suited for a material like asphalt, gravel, and sand.

- They not only give a smooth finish but also do a good surface sealing of the material.

- These machines are used for the stages of road surfacing and final compaction. Nevertheless, relying mainly on weight they are almost powerless in the case of deep compaction of cohesive soils.

Pneumatic (Tyred) Rollers

Instead of steel drums, these are equipped with multiple rubber tires.

- On those machines the process is working differently, they incorporate a kneading method instead of a regular static one, which makes them perfect for asphalt layers.

- Such machines are used between the paving and the final product stage to eradicate voids.

- They allow for even and consistent compaction of unlevelled surfaces as well as give the possibility of working in various conditions.

Vibratory Rollers

These are powered by the dysfunction of eccentric shafts or weights inside the drum that generate vibrations.

- One of the most prominent uses is for granular soils and asphalt in general, where they become extremely efficient.

- Vibration makes particles rearrangement and density improvement possible.

- They are typically seen in highways, airports, and places where heavy-duty foundations are constructed.

Sheepsfoot Rollers

These rollers have drums equipped with protruding “feet” or lugs that can grip the ground.

- They are one of the main components for the development of clayey or cohesive soils.

- When they are rolling, the feet will be deep into and press down the layers that are under the surface.

- After a number of repetitions, the surface becomes compact and even.

Grid Rollers

The drum of a grid roller is made of steel mesh, or it has a lattice pattern, it can break and compact large gravel or rocks.

- They are applied in road subgrade preparation as well as in the manufacturing of base layers.

- One of the strongest sides of the machine is the capability to crack the large aggregates that are difficult to be broken.

Every single type of roller has its positive sides — in fact, road construction projects usually combine different types of rollers in order to get the required level of compaction.

Key Components and Design Features

Here is a sneak peek into the different parts of a road roller and the features that make it a road roller.

Engine and Powertrain

Rollers are mostly powered by diesel engines, the power of which varies from 20 HP for small models to more than 200 HP for big vibratory units. The engine spins the drums and supplies energy for the vibration system through hydraulics.

Drum or Wheel Configuration

The main part of the roller is the drum.

- Single drum rollers come with a front drum and rear tires, which are suitable for soil compaction.

- Double drum rollers (tandem rollers) consist of two steel drums with no tires, so they are used for asphalt surfaces only.

Vibration System

As for the vibratory rollers, the eccentric shaft mechanism is the one that brings about the vibrations. Operators can vary the frequency (Hz) and the amplitude (vibration depth) as per the soil type.

Operator’s Cabin and Controls

Comfort and safety are the priorities in the design of modern rollers. The features of the cabin are:

- Comfortable seats with adjustable positions.

- Air conditioning (only available in the more expensive models).

- Easy-to-understand control joysticks.

- For safety during the turning, 360° visibility is provided. The safety factor is enhanced in some machines by the presence of anti-vibration mounts that lower the fatigue level of the operator.

Safety and Monitoring Systems

- Emergency shut-off switches.

- Seatbelt and rollover protection structures (ROPS/FOPS).

- Onboard diagnostic systems keep track of engine temperature, fuel, and vibration performance.

Applications of Road Rollers

Road rollers are not only used on roadways, but also are indispensable in different civil engineering projects.

Road Construction and Repair

Their first and foremost task is the compaction of layers of soil, gravel, and asphalt which is a part of road building. The work of rollers leads to the tight binding of materials that allows a durable and smooth surface to be formed that will be able to resist heavy traffic.

Airport Runways

Because of the massive loads that airport runways have to support, their compaction has to be of the highest standard. Vibratory rollers and pneumatic rollers are employed to achieve such a high degree of uniformity.

Dams and Embankments

Massive civil works like dams need layers of soil that have been compacted to prevent the flow of water through them. Herein sheepsfoot rollers are used most widely due to their effectiveness in the depth of penetration.

Landscaping and Site Preparation

You can use small rollers to compact the soil for the driveway, lawn, or path that you want to build.

Industrial Flooring and Foundations

Rollers are used in industries and warehouses to make the base of the concrete slabs and floor installations that are of the desired strength and evenness.

Top Manufacturers and Popular Models

The global road roller market is generally composed of a handful of the world’s most distinguished brands which enjoy a reputation for perfection in engineering, reliability, customer service. Those are the leaders:

Caterpillar (CAT)

Caterpillar is absolutely one of the most historical brands among construction machines. Deriving from their product line, the factory-made rollers like the CAT CB13, CS44B, and CB1.7, stand out for high compaction productivity, intelligent management, and excellent durability. Basically, many models are now fitted with the Compaction Meter Value (CMV) technology which allows monitoring of the density continuously.

Bomag

Bomag is a German firm whose concentration is fully focused on the manufacture of compaction machines. The company has been setting the benchmark in this industry since the 1950s. Their BW range (BW120, BW213D-5, BW211D) covers the spectrum of walk-behind rollers to heavy-duty soil compactors. The ECOMODE feature enables users to reduce their fuel consumption by as much as 30%.

Dynapac

Dynapac from the beginning is a brand of Sweden that is Dynapac is a vibratory roller technology powerhouse. The company is mainly known for models such as CA1500D and CC4200. Their machines feature operator comfort, exact compaction, and advanced vibration control as the core of the design.

Wacker Neuson

This brand is more concentrated on smaller compactors and tandem rollers. They can be used for the maintenance of the city, walkways, and minor asphalt projects.

Hamm (Wirtgen Group)

As a member of the Wirtgen Group (now under John Deere), Hamm is a leading roller brand that is widely recognized for its breakthrough ideas. The HD series and HC compactor are commonly used in infrastructure projects all over the world.

Indian and Chinese Brands

For small to medium contractors, multi brands like ACE, Sany, Liugong, and XCMG may offer suitable choices at reasonable prices with acceptable reliability. Indian brands are catching up very quickly and delivering affordable machines for local use.

How to Pick the Right Road Roller for Your Project

The proper road roller selection can have a major impact on both cost and success of the project. Follow the steps outlined below to make the right decision.

Define The Material Type

- Granular soils (sand, gravel): Apply vibratory rollers to achieve maximum performance.

- Cohesive soils (clay): Use the sheepsfoot roller to lower the water table and make the ground firm to the required depth.

- Asphalt: Utilize tandem smooth rollers or pneumatic rollers.

Consider Project Scale

- Walk-behind or mini roller will suffice if the contractor is limited to small construction or landscaping work.

- If there is a need to build highways or large surfaces, then a double-drum vibratory roller will be your vehicle.

Terrain and Accessibility

In the case your works area has slopes or is rough, choose a single-drum roller that is equipped with tires so that you get a better grip on the ground.

Budget and Operating Costs

Apart from the prices, a roller should be evaluated also in terms of fuel efficiency, spare parts, and maintenance costs. The total cost of ownership (TCO) is what you should always have in mind.

Attachments and Tech Features

The modern road roller is equipped with a GPS system as an option, a sensor for measuring compaction and telematics. The latter can be very useful in the case of government work or contract-based work facilitating compliance and performance tracking.

Advantages of Using Modern Rollers

The latest road rollers are not only heavy steel drums, but they are also smart, efficient, and safe machines. They are so much in demand due to the following reasons:

High Compaction Efficiency

Compared to traditional static models, the vibratory rollers get up to 30–40% faster compaction rates. This means that less time and less fuel are needed for the project to be finished.

Consistent Surface Quality

Thanks to the vibration control, frequency adjustments, and compaction monitoring, modern rollers give a stable surface even in changing soil conditions.

Operator Comfort & Safety

The machines of today have ergonomic cabins, air suspension seats, noise reduction, and even joystick steering, for the comfort of the operator. In addition to that, anti-vibration mounts save operators from continuous fatigue resulting from long periods of work.

Reduced Fuel Consumption

Brands like Bomag and Hamm are the ones who enable Ecomode on their roller which leads to fewer fuel consumptions (up to 25%) as the engine speed is matched with the load.

Smart Compaction Technology

Rollers are equipped with IoT and GPS sensors more and more. The systems that come with Cat Compaction Control by Caterpillar and Seismic by Dynapac are designed in such a way that they can adjust the vibration frequency automatically depending on the ground stiffness.

Environmental Benefits

Basically, the improvements in engines and emissions standards (Tier 4 Final / BS IV) have helped carbon emissions from modern rollers to reduce significantly. The machines are quieter and more eco-friendly than before.

Maintenance and Safety Practices

Proper care will not only extend the life of your road roller but also keep it operating at its best. The essential tips are the following:

Daily Maintenance

- Check engine oil, hydraulic fluid, and radiator water levels first thing in the morning before operating.

- Check the drum surfaces for any buildup of dirt or debris.

- If you find any loose bolts or hydraulic connections, then try to tighten them.

- Look at the tire or track conditions to see if there is any wear and tear.

Periodic Service

- It is good to follow the recommendations of the manufacturer and replace the filters, belts, and hoses regularly.

- Particularly the cleaning and inspection of the vibration mechanism should be done on a regular basis.

- To avoid rusting, lubricate the pivot points and the joints caused by the aging process.

Storage and Transport

If you always park in the wrong place, then you should at least choose a strong and flat ground to park. When you transport make sure the wheels are properly secured with wheel chocks and chains.

Operator Safety

- Make sure that operators who wear seatbelts and the PPE are trained.

- Do not attempt to reverse or turn sharply on a slope under any circumstances.

- During vibration mode, keep spectators at least 3 meters away from the machine.

- Generally, do not operate on ground that is too wet or unstable for safety reasons.

Common Mistakes to Avoid

- Excessive vibration of asphalt can lead to the development of cracks.

- Not enough passes will result in an uneven distribution of compaction.

- Overlooking the signs of a break-in process for the machine can lead to breakdowns that cost a lot to be fixed.

Fuel Efficiency and Environmental Factors

Among other consequences, rising fuel prices and stricter emission regulations make efficiency and sustainability the first priorities of the modern construction industry.

Engine Technology

Car-makers are offering the new diesel engines with more rigorous combustion control. The Tier 4-powered engines go a long way in cutting almost all emissions.

Smart Vibration Control

The automation has changed the method in such a way that they now change the vibration amplitude and frequency on the fly only to save energy and to avoid unnecessary wear.

Hybrid and Electric Rollers

There are already a few brands like Ammann and Volvo that are producing and testing the electric rollers that have zero emission, work noiselessly, and have lower maintenance costs.

Sustainable Compaction Materials

Certain paving is done with recycled asphalt pavement (RAP) and geotechnical stabilizers, which help in diminishing the project’s impact on the environment.

Operator Training and Eco-Mode

The training of the operators in proper roller usage (throttle control, vibration timing, EcoMode) will not just save up to 15% fuel but also bring the machine’s lifespan up.

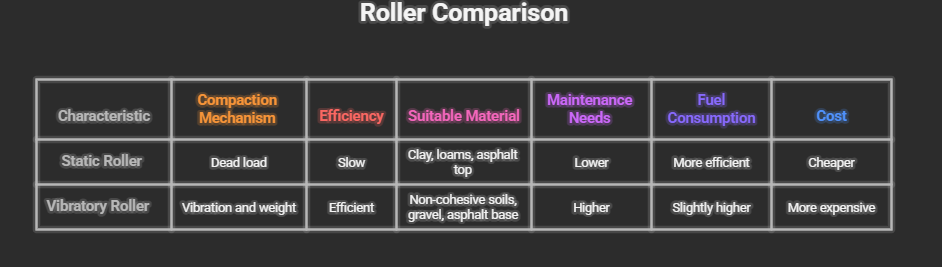

Comparison: Static vs. Vibratory Rollers

Road rollers are mainly different from each other depending on whether they are static or vibratory, each with unique features and applications. Proper understanding of their differences will let you choose the most appropriate one for your project.

Simple comparison:

- Static roller = works better on finishing layer, compaction depth limited.

- Vibratory roller = works faster with deeper compaction.

For example, at the large scale of a highway or an airport, the use of vibratory rollers is standard. Nevertheless, if it is about fixing or laying finishing layers of pavements or roads, static rollers are still the ones relied on most.

Challenges in Using Road Rollers

Road rollers have a significant function in the construction process; however, they face certain operational as well as logistical issues that are to be solved by the engineers.

Terrain Limitations

Working rollers on very steep hills or loose ground can be extremely risky. In the case, the surface is not stable enough then heavy rollers might get off or fall over.

Over-Compaction

Rolling the material excessively may cause its cracking or loss of elasticity, mainly in the case of asphalt layers. The experienced operator

Maintenance Downtime

Injecting oil in the wrong place, unbalance of the drum or vibration system failure can result in a halt that will be expensive to the company. Preventive maintenance is a very important upgrade.

Transport and Logistics

Road rollers take up a lot of space and transporting them requires flatbed trailers. Improper handling during the loading/unloading phase may result in the release of the drum.

Weather and Temperature

Too much cold can freeze the asphalt and a hot stretch can make it soft. Both of these factors can render the roller not working properly.

12.6 Fuel and Emission Costs

Although there is more demand for cleaner construction, the non-compliance diesel engine which is the source of the pollution is under the radar of the strictest limitations – thus older machines are faced with the increasing of costs.

But there is always a solution to hard times: correct training of the staff, modern machinery, and good maintenance practices will help to reduce the risks as well as increase the output.

Latest Innovations and Future Trends

The technology of road roller has totally changed from the iron cylinders pulled by horses. Automation, data analysis, and sustainability are the main points of the new generation of compactors.

Intelligent Compaction (IC)

Intelligent Compaction devices consist of GPS map and inbuilt sensors that capture the data of compaction at the moment. Operators can immediately recognize those spots that require further treatment, thus no guessing is left.

Telematics Integration

Caterpillar, Dynapac, and other manufacturers are now installing a remote monitoring system on their equipment which informs the manager of the fuel consumption, gives the maintenance alerts, and records the operator’s efficiency level.

Hybrid & Electric Powertrains

To recap, the era of electric rollers is about to come with pilot productions being rolled out. They are emission-free, very quiet, and the maintenance part is reduced by 30–40%.

Autonomous Rollers

There are some companies that are working on self-driving rollers that are capable of doing their jobs without any supervision and on pre-programmed paths. These rollers help to improve accuracy and also reduce the need for labor.

Recycled Material Compaction

The new rollers are designed to be more efficient in compacting recycled asphalt pavement (RAP) so as to encourage the construction industry to be more environmentally friendly.

Ergonomics and Safety Enhancements

More noise insulation cabins, smart. visibility cameras, anti-vibration platforms and also stopping systems that work automatically are some of the features that usually come as a package in future durable models of road roller.

It’s true that the next generation of road rollers will leverage digital technology all the way — the machines will be more intelligent, more secure and more eco-friendly.

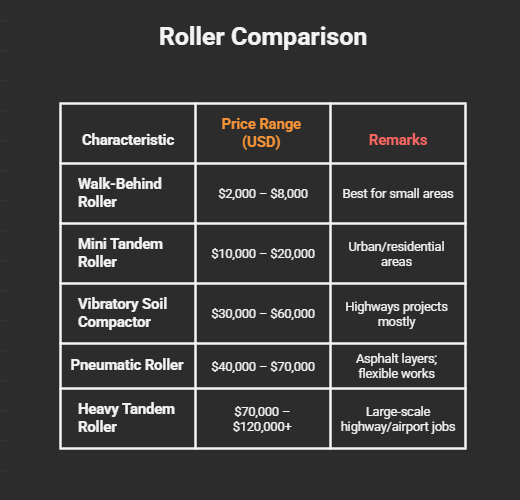

Cost Factors and Buying Tips

The price of a road roller is influenced by several variables: the kinds of models, the brands, the drum vehicles, the power, and the features. To better plan your budget, here is a detail breakdown of each impacting factor.

Cost Range (Approximate)

The prices in India vary from ₹4 lakh for small rollers to ₹80 lakh+ for premium models.

- Engine power — the higher the horsepower, the higher the price and the productivity of the machine should be expected.

- Technology — the application of intelligent compaction, GPS, and telematics to the machine can only increase its cost.

- Attachments and configuration — the dual-drum and vibratory systems are more expensive than standard ones.

- After-sales support — brands with local service centers are preferable.

Buying Tips

- Define your job type — are you going to work on soil, asphalt, or will your machine be multipurpose?

- Inspect the machine — make sure to check the drum wear, hydraulics, and the vibration system.

- Ask for demo or test — check on the performance under load.

- Verify warranty — make sure that the coverage is on a few of the key components such as the engine and the hydraulics.

- Check spares availability — parts should be accessible locally.

- Consider resale value — popular brands are the ones that retain value for the longest period of time.

Purchasing a roller is a long-term investment — it’s better to pay more upfront for a reliable unit than lose productivity to breakdowns later.

Conclusion

Road rollers are the foundation of every smooth, durable road that we can drive on. They turn loose soil and asphalt into compacted layers that are strong and will last both time and traffic.

Through the use of sensors as well as other technological features, these modest machines have now become accurate and precise tools. As a matter of fact, this technology is used not only for road construction, but also for building airports and industrial foundations.

Therefore, the quality, the safety, and the economy that comes along with the most suitable roller, are the main factors which a good choice of a roller will guarantee.

Summing up the main idea — a properly selected road roller doesn’t solely level the ground; but actually, it does construct the base of progress.