Free Shipping Within USA | 1-year Warranty

Core Mini Excavator Parts: What You Need to Know about Diesel Engines

Mini excavators are essential tools across various industries, from construction and mining to agriculture. These compact yet powerful machines offer a unique blend of efficiency, precision, and versatility that larger equipment can’t match. At the heart of their performance are the various mini excavator parts, each part playing a specific role in operational efficiency. This guide will delve into diesel engines, a pivotal component of mini excavator parts, exploring its roles, components, and what are the popular diesel engines, to help you learn more knowledge about mini excavators and make better- informed decisions.

Why is Diesel Engine Important for Mini Excavators?

Have you ever wondered why the diesel engine is considered the core part of a mini excavator? It all comes down to its unmatched efficiency, exceptional durability, and formidable power. Unlike gasoline engines, diesel engines offer higher torque output and superior fuel efficiency, making them ideal for the heavy-duty tasks that mini excavators handle. Whether digging foundations or performing demolition tasks, the engine’s power output directly impacts how quickly and effectively these jobs are done.

Detailed Look at Mini Excavator Engine Parts

Mini excavator diesel engines are composed of several critical components, each playing a unique role in converting diesel fuel into mechanical energy. Let’s take a closer look at these diesel engine parts and understand their importance in the overall performance of mini excavators.

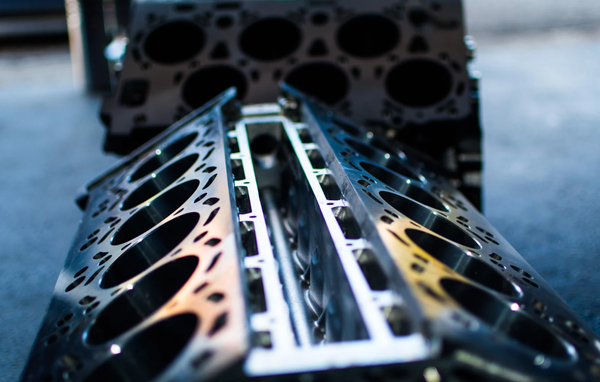

01. Cylinder Block

A cylinder block, typically made from durable materials like cast iron or aluminum, houses the engine’s cylinders and other vital components. It not only supports the substantial weight of the engine but also helps transmit the power generated from fuel combustion to the excavator’s operational machinery.

02. Cylinder Head

Mounted on top of the cylinder block, the cylinder head contains vital parts such as the intake and exhaust valves, fuel injectors, and the combustion chamber. Its job is to seal the combustion chamber, allowing the fuel and air mixture to enter the cylinders and facilitating the exit of exhaust gasses. This sealing function is vital for maintaining the efficiency and effectiveness of the engine’s combustion process.

03. Piston

Pistons are cylindrical components that move up and down within the cylinder block. Driven by the energy released from fuel combustion, they convert this energy into mechanical power that operates the mini excavator. The design and durability of pistons are crucial for the reliable conversion of fuel energy into usable mechanical force.

04. Connecting Red

The connecting rod’s primary function is to link the piston to the crankshaft so that the crankshaft can transfer the linear motion of the piston into the rotational motion.

05. Crankshaft

The crankshaft is a larger shaft that turns the linear motion of the piston into rotational motion.

06. Camshaft

The camshaft controls the timing and operation of the valves. Driven by the crankshaft through a timing belt or chain, it ensures that the intake and exhaust valves open and close at precisely the right times during the engine cycle. Proper functioning of the camshaft is essential for optimal engine performance, as it directly affects air and fuel flow and the expulsion of exhaust gasses from the engine.

Valves

Located in the cylinder head, valves are crucial for controlling the flow of air and fuel into the engine and managing the exit of exhaust gasses. There are two types of valves: intake valves, which allow the air and fuel mixture to enter the cylinder, and exhaust valves, which let the exhaust gasses escape. Effective operation of these valves is essential for

maintaining the engine’s power output and efficiency. Understanding these components of a mini excavator’s diesel engine helps in better maintenance and more informed operational decisions, ultimately extending the lifespan

and enhancing the efficiency of these powerful machines.

Popular Mini Excavator Engines on the Market

01. The Kubota D722-E3B Engine

The Kubota D722-E3B engine powers mini excavators with smooth and reliable operations. Renowned for its use in various applications over 25 years, this engine has set industry standards for reliability. It also adheres to EPA Tier 4 emission standards, making it one of the cleanest engines in its class. Looking for mini excavators equipped with Kubota D722-

E3B engines at a competitive price? Just visit AHM 1.1 ton mini excavator with 13.8 HP Kubota D722 engine.

13.8 HP Kubota Engine 1.1 Ton Mini Excavator with 5.7 ft. Maximum Digging Depth

02. The Briggs & Stratton 25T2 Engine

With a gross power of 13.5 HP at 3600 rpm, the Briggs & Stratton 25T2 engine offers impressive power output. Its operational lifespan is three times longer than the Briggs & Stratton CR Series. With a forged crankshaft and Dura-Bore™ cast iron sleeve, the 25T2 engine can exceed the rigorous demands of modern excavation environments, ensuring reliable and long-lasting performance. Looking for mini excavators equipped with Briggs & Stratton 25T2 engines at a competitive price? Just visit AHM 1 ton mini excavator with 13.5 HP B&S engine.

13.5 HP 1 Ton B&S Engine Mini Excavator with 2600 lbf Digging Force

03. Cat C2.4 Turbo Engine

The Cat C2.4 Turbo engine drives performance with impressive stats: 55.9 hp under ISO 9249 and 57.9 hp under ISO 14396. With a bore of 87 mm and a stroke of 102.4 mm, it offers a displacement of 2.43 liters. This engine also meets compliance with EPA Tier 4 Final and EU Stage V emissions standards, ensuring environmentally friendly operations.

04. Komatsu 4D88E-7 Engine

With a 4-cylinder configuration, this Komatsu 4D88E-7 engine delivers robust performance with a gross horsepower of 39 HP (SAE J1995) at a rated RPM of 2400. The engine has a water-cooled, 4-cycle, and direct injection design. Furthermore, being committed to environmental sustainability, this engine also meets and is certified under EPA Tier 4 Final emissions standards.

05. 3TNV76-QBVA Yanmar Diesel Engine

The 3TNV76-QBVA Yanmar diesel engine delivers a gross power of 13.5 kW at 2100 rpm. With a displacement of 1.116 liters, it provides a maximum torque range of 63.4 to 69.2 N.m at 1600 +/- 100 rpm, ensuring robust power for demanding tasks. This combination of power, efficiency, and reliability makes the 3TNV76-QBVA Yanmar diesel engine a good choice for rigorous excavation projects.

In summary, the effectiveness of mini excavators hinges significantly on the quality and reliability of their engines. For those looking to purchase or maintain a mini excavator, prioritize genuine parts and consider the engine’s brand reputation in your decision- making process. Remember, the right part of a mini excavator means both better performance and extended machinery life.