Free Shipping Within USA | 1-year Warranty

Typhon Attachments – The Power Extenders of Modern Machinery

Introduction: The Evolution of Typhon Attachments

In a competitive market where heavy machinery is the king, raw power is still not sufficient – what really matters is the machine’s ability to adapt. This is the fundamental idea behind Typhon Attachments, the utilitarian accessories that make an already powerful machine from Typhon Equipment a mighty but versatile multi-functional machine. As the mythological Typhon—the tempest god who assumed numerous forms—these attachments literally carry the attributes of change, dominate, and survive the nature or the challenge thrown at them.

The company designs Typhon Attachments to do the job that the machines of Typhon can’t, by extending their reach, intelligence, and efficiency, thus, making them suitable for various applications such as excavation, demolition, forestry, mining, and agricultural.

While other heavy machinery brands may opt to stop at just providing a greater power capacity, Typhon takes it a notch higher by developing tools that can keep up with the rapid changes of the job.

Besides, the firm has gone on to incorporate AI technology into its already revolutionary alloy-built machines. These smart systems bring in features like load control, predictive wear monitoring, and real-time terrain calibration.

How about the case of an excavator that does not merely digs but also figures out the soil nature and accordingly uses optimal grip and torque? What if a crane attachment could counterbalance itself during an unexpected gust of wind?

Could a hydraulic hammer that conserves fuel by lessening the impact without sacrificing the output be real? These are not mere fantasies but facts in the world of Typhon Attachments, where metamorphosis is the rule rather than the exception.

Typhon Attachments came about as a result of a requirement.

As industrial growth and task complexity kept escalating, the engineers at Typhon realized that customers would demand such machines as their goals, i.e., machines as versatile as the customers’ ambitious themselves. One machine had to do the work of many—causing the saving of time, cutting down of money, and increasing of versatility.

It is this insight that gave rise to the development of a range of attachments that could effortlessly link up with Typhon’s system—a standard connection that allows quick changes of tools with no interruption of work.

The utilization of these global Typhon Attachments is no longer a secret or resorted to a few places only. They are found almost everywhere – in the constructions sites of cities, in the open-pit mines, in the forests, and even on large farms. They are a perfect example of the fusion of power, smartness, and economy of effort—the modern portrayal of the Typhon storm: potent, adaptable, and always evolving.

Understanding the Typhon Philosophy: Versatility as Power

The one big idea that underlines the whole Typhon Equipment is the idea that power is not just a matter of brute force, but fundamentally adaptability.

Therefore, the philosophy governing the creation of Typhon Attachments is the idea of making the devices which in turn can be used to transform any Typhon machine into a customizable, multi-functional powerhouse. Just like Typhon, the mythic storm god, who could change his form and had power over the elements, Typhon’s contemporary machines can be changed to solve any problem—simply by changing the attachment.

Versatility, for the Typhon engineers, is not something which can be chosen but a necessity that comes with survival. The need for the industrial sector is constantly changing, and each worksites are different from one another.

A project that might call for demolition on a certain day, precision lifting or fine grading could be needed the following day. Instead of using multiple machines, a single unit equipped with Typhon Attachments has the capability of playing several roles.

The transformation does not stop at work processes but goes further to an entire shift of business models thus, industries get to operate at a quicker, smarter, and more affordable pace.

Although the philosophy is about adaptability of the machines, the company embraces this as part of their identity. Just like the myth of Typhon was about chaos and transformation, Typhon Equipment faces complexity as a means to achieve control. Typhon’s attachments are a real-world embodiment of that concept.

Each one is designed to be easily installed, automatically recognized by the system, and fully optimized through the machine’s onboard AI. In fact, the very instant an attachment is secured, the system goes on to adjust hydraulics, balance, and power output automatically and in real time. So, in just a few moments, a Typhon excavator can change from being a heavy digger to a precise rock breaker or a soil-grading specialist.

In order for the versatility of Typhon not to sacrifice the reliability aspect, the company’s engineers observe the so-called Storm Balance Doctrine or a principle which states that each and every attachment should be equally as powerful as the core machine.

This implies that every component in the machine, be it the hydraulic couplers or the cutting edges, is made from Typhon’s patented alloy—material that has been recognized for its outstanding strength-to-weight ratio as well as its abilities to resist heat, friction, and corrosion.

The upshot of such work is attachments which are not only capable of performing under heavy load situations but can also perform with graceful efficiency.

The transformation theme in this case is not just the mechanical one but also a symbolic one. Typhon regards its equipment as prolongation of human capability—means which empower the workers to transform their environments with the very same might and accuracy that were used by the gods when they ruled over storms and mountains.

Be it a task that involves unloading tons of steel in a crowded city or one that requires making a new trail in the woods, Typhon Attachments are the perfect representation of the human will-machine evolution partnership.

Each and every piece of munitions labeled with the Typhon brand is a narrative of the conquest of disorder. However, it is the attachments—the claws, the blades, the lifters—that really make that control tangible. They are the hands of the storm, created to change the world by dealing with one challenge after another.

However, flexibility is not only about speed; it is also about accuracy and consistency. Typhon makes sure that every attachment fits perfectly, thus, the machine’s center of gravity and safety during operation are maintained.

In fact, the attachments are equipped with coupling points that are made of high-torque resistant and absolutely leak-proof material. Hence, full performance is assured even in unstable situations like mining pits or high-pressure construction zones.

One major difference of Typhon from its rivals is the customization ecosystem. Customers don’t only get standard attachments, but they have an opportunity to work directly with engineers from Typhon to create the tools that are uniquely the way of their projects.

Be it a specially dredging head for underwater excavation or a plasma-cutting rig for precision demolition, Typhon’s engineers make sure that every attachment is seamlessly integrated into the architecture.

Such a step is not just a technical upgrade, but a company philosophy change. Typhon has in a way revolutionized industrial machines to be not just fixed assets, but dynamic, shapeshifting systems. The idea is no longer about buying a machine for every task, but about putting money into one Typhon platform which can be converted into anything the work requires.

Simply put, Typhon did something quite revolutionary for the industries – it gave them freedom. Freedom from downtime, inefficiency, and limitation. Now similar to its mythological namesake, Typhon’s machines have the ability to change form whenever they want – powerful, flexible, and invincible.

Engineering Brilliance Behind Typhon Attachments

There is a blend of engineering precision, material science, and intelligent automation behind every Typhon attachment which is like a symphony.

To the eyes of the laymen, these may appear as commonplace tools—buckets, breakers, grapples, augers—but in reality, these are the masterpieces of 21st-century engineering, each fabricated to function as the companions of the power machines of Typhon. Not one of the bends, joints, or seams is by chance; each is a design choice optimized for utmost strength, durability, and smoothness of the movement.

Typhon’s engineering philosophy for the attachments is centered on what they term “The Storm Equation”—a design principle that balances three forces: pressure, motion, and control.

The concept is elemental to the point of being revolutionary: a mere sleeve of the attachment shouldn’t suffer the force—but rather the force should be redirected. Instead of battling the gargantuan power of the machine, Typhon attachments in fact employ accurate geometry and energy allocation to magnify it.

For instance, the Cyclone Bucket System by Typhon, in simple words, is to be taken as an example of one of its most prominent inventions. Standard buckets use the sheer hydraulic power of the machine to break down rock and soil, which can cause the parts to wear and lose power.

However, the Typhon’s bucket uses a patented spiral-cut design that not only directs the impact pressure along its frame but also allows the frame to absorb the impact uniformly.

This process is responsible for both the reduction of metal fatigue by as much as 30% and the increase of the digging efficiency near to 40%. What is the outcome? More work is done with less energy – a flawless representation of the Typhon ideal.

Mitigation of vibration is another brainchild of Typhon engineers behind the curtain effect. Among the sources of the problem are heavy tools like hydraulic hammers and augers that produce rapid and strong shaking due to their operation, which causes the gradual wear of the machines to which they are attached.

With the help of Typhon’s Technology the vibration energy is reduced fractionally to a quarter or so and the leftover is then converted into kinetic heat and then discarded through the thermal vents. The innovation here not only prolongs the attachments’ lifespan but also greatly reduces the tiredness of the operator, thus making it safer and more comfortable for the operator to work for a long time.

The creations rely on sophisticated Finite Element Analysis (FEA) simulations for their design. Engineering teams virtually reproduce the scenarios where the product is stressed; they also examine fluid and air dynamics and weight aspects before the very first prototype is even made.

Upon the decision to proceed, the parts of the attachment are geographically cut, robotically assembled, and covered with the Typhon, which grants the finished product resistance to rust, wear, and heat without parallel.

Types of Typhon Attachments and Their Core Functions

The core of Typhon Equipment power is its versatile capability, and this is not more clear than the huge array of Typhon Attachments. These attachments change Typhon’s machines from being only one powerful machine to be a tool that has many functions and can still be a boss of any worksite.

In fact, whether it is ripping through a rock, lifting a hundredweights of steel, cutting down trees, or grinding up the remains, Typhon’s attachments are made to be the ones to prevail in every challenge.

Basically, each category of the attachment is a set of different functions but sharing the same trait — Storm-Level Performance: the ability to achieve the maximum output with an intelligent efficiency. Just to name a few, these are the main Typhon attachment families and functions that make them a must-have throughout the industries.

1. Excavation Attachments

Excavators are the main featured-extension-power of Typhon’s attachment ecosystem by which are built to incise, scoop, and transfer the ground in a very accurate way with a high level of endurance.

- Cyclone Bucket System: Typhon’s primary earthmoving bucket is equipped with reinforced edges and a spiral-cut design that expands penetration efficiency while cutting fuel consumption drastically.

- Raptor Claw Bucket: Its curved talon-like teeth are made to tear the most heavily compacted materials which are rocky and frozen, and these are the grounds where the standard buckets do not work.

- Digging Arm: This arm extends the machine’s reach to 10 meters and is great for underwater dredging and deep foundation work.

- Auger Series: The main focus of this auger series is the drilling through soil, ice, and sediment layers with the vibration dampers used for smooth precision drilling.

Moreover, all of the excavation attachments are programmed to work with Typhon’s and AI systems simultaneously, thus, the adaptive torque control varies according to soil composition, depth, and resistance.

2. Lifting and Crane Attachments

Besides that, Typhon attachments are the perfect choice when the problem is to lift the unthinkable, as they completely change the meaning of balance and control.

- Crane Hook: This hook is able of carrying loads up to 500 tons making use of the weight very fast and in real-time. The smart sensors installed in it automatically make the machine balance correct by itself.

- Winch System: A winch with two engines and a double-motor is the solution for the aerial and marine lifting operations, this system is also resistant to corrosion and different pressure between the two sides.

- Electromagnetic Lifter: The main idea behind this lifter and the main reason for its usage in heavy steel works and scrap yards is the availability of the variable magnetic intensity feature for safety and precision purposes.

- Hydraulic Claw: With great versatility, it can be mounted on the transport vehicle and used for mobility, and material sorting purposes as well; Among the most important features of the anti-slip micro-movement sensors are the prevention of dropping triggered by movement.

Those attachments can be controlled by Typhon’s Intelligent Load Management System which is monitoring constantly the tension, gravity vectors, and mechanical strain apart from that it shows the malfunction in real-time thus, overloading risks are almost entirely taken out.

3. Demolition Attachments

If destruction is viewed as an art, then surely Typhon is the master of it.

- Hydraulic Hammer: Through impact modulation it melts the target area with minimal recoil creating the most powerful destruction with the least amount of waste.

- Concrete Cutter: Is a cutting attachment that uses a plasma edge for the cleanest and fastest cuts in the most tightly reinforced concrete and steel frameworks.

- Shear Attachment: Structural demolition in confined spaces without the risk of the surroundings being damaged is what this device has been designed for and it provides accurate and clean cuts.

The Impact Sense AI is also installed in these tools; it measures the density of the material and based on that, modulates the energy output, thus, achieving not only efficiency but also safety on very demanding demolition sites.

4. Earthmoving and Ground Compaction Attachments

When it is a matter of changing the terrain itself, Typhon’s earthmoving attachments are the protagonists.

- Grader: It angles the blade and guides the laser with the help of AI for flawless ground leveling that is even beyond human precision.

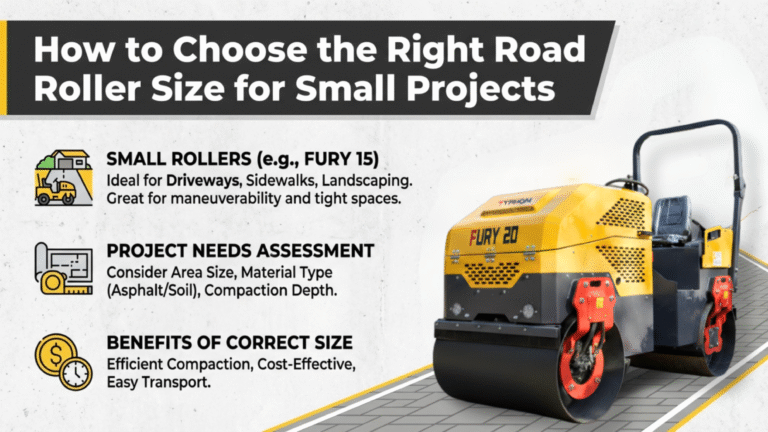

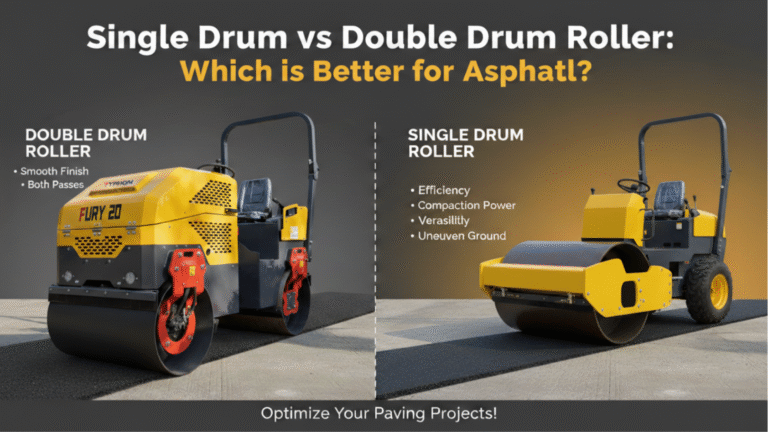

- Compactor: The dynamic weight modulation used for uniform ground compaction is the feature of the roller attachment which is powered by a hydraulic system and is used for soil compaction.

- Shovel System: The most efficient design for the fastest reshaping of sand, gravel, or snow is this system in which the least possible resistance is ensured.

- Pivot Head: A 360° rotation is what this upgrade for earthmovers provides and, thus, making it capable of the complex tasks such as shaping, slope forming, and trench finishing.

All these are complemented by the Typhon’s Cyclone Intelligence Platform which not only surveys the surface but also changes the hydraulic resistance accordingly for the best result of evenness of the ground.

5. Industrial and Agricultural Attachments

Typhon’s adaptability is not limited to the construction sector, it is merged with the agriculture, forestry, and logistics sectors as well.

- Forestry Saw: With one-meter-and-a-half-diameter trunks carbon-tipped blades are able to cut through the trunks.

- Loader Forks: The multi-purpose handling is an attachment for loaded hay bales, logs, or pallets with your adjustable torque sensitivity.

- Sprayer Boom: A precision-controlled agricultural sprayer, which uses AI to analyze plant density and also regulate fluid output.

- Rotary Sweeper: The industrial-grade cleaning attachment that can be used for clearing of construction sites, roads, or warehouse floors by using kinetic sweep control.

Typhon’s farm machinery range is geared towards productivity and environmental friendliness—devices that are in harmony with nature, rather than waging a battle against it, which is in line with the company’s eco-conscious vision.

Conclusion: The Legacy of Power and Adaptability

Typhon has redefined the very essence of industrial change-time with inventions ranging from the first blade of a claw to the latest AI-powered unit-with its name.

A phenomena which started with a mere search for constructing more durable machines has converted into a concept- a living idea that these days to be strong is of no use if you lack flexibility and to be smart without a reason is throwing away your intelligence.

Now, the first word to come into one’s mind when hearing of a “Typhon Attachment” is innovation which is the core idea made of invention and technology that what it is in fact.

Typhon Attachments, the indispensable suppliers to modernization, can be seen everywhere: They are the silent engineers behind progress carrying out their work in the shafts of the mines, woods, the vast blue sea and even in metropolises, and across different continents. These machines are the ones that dig for the new cities of the future, they clear the forests to build the roads that take us there, and they erect the buildings that stretch the sky.

The adaptability of the machines makes it possible for only one device to do the work that used to require several, their intelligence guarantees safety and work productivity, and their toughness challenges the destruction forces of nature.

The saga of Typhon continues through each invention that it has made: recovery, and ILMS safety protocols. All of them together make up a precision and dependability storm that is changing the hard work of the industry heavy beyond anyone’s initial expectations. But beyond the brilliance in engineering, Typhon’s ultimate inheritance is conceptual.

It proves that advancement does not derive from opposing the natural environment, but from figuring out ways to control it-transforming disorder into design, destruction into renewal.

It is the sentence which expresses most vividly the idea behind Typhon’s being- the brand which recognizes technology not as a finish line, but as a transformative force- power with a purpose, strength merged with vision, not a storm of chaos, are the things which the metaphorical storm conveys.

While Typhon is preparing for its future chapter featuring adult intelligence, quantum computing, and interplanetary engineering, the company is still holding on the same rule which was the foundation of the whole story: either adapt or be left behind by the world you want to build.

The storm does not show any signs of stopping but rather goes on moving forward—louder, smarter, and more unrelenting than ever. And the Typhon name will forever be there mixing with the sound of the storm as a hallmark of human creativity, stamina, and the endless desire for change.