Free Shipping Within USA | 1-year Warranty

Maximizing Efficiency with Compact Excavators

Compact excavators or mini excavators, are multipurpose machines that have attracted a lot of attention in the construction and landscaping sectors.

The main feature of these machines is their small size, usually with a weight of 1 to 10 tons, which permits them to work in a closed area where large excavators cannot move. Compact excavators usually have a rotating boom and a hydraulic arm, which makes them capable of performing operations like digging, grading, and lifting.

Their layout can also include the zero tail swing or no tail swing function, which indicates that the counterweight does not swing out past the tracks, hence being very suitable for city environments and small job sites.

The comprehensive utilization of compact excavators can even go further as the company can attach various attachments such as buckets, augers, and hydraulic hammers.

This feature extends the operator’s ability to move from one job to another quickly, making them the most helpful for jobs starting from residential landscaping to utility installations.

The hydraulic system can give a machine the ability to lift heavy loads, but the precision necessary for delicate operations is also vital and is what is done by these systems. The popularity of efficient and space-saving tools is steadily increasing and, as a result, compact excavators have become one of the essential pieces of equipment in today’s construction.

Key Takeaways

- Compact excavators are versatile machines that can be used for a variety of construction and landscaping tasks.

- The choice of a suitable compact excavator for the job basically revolves around the consideration of a number of different factors such as the area, the desired depth, and the reach, and the characteristics of the excavation.

- Yes, the proper service along with love and care for the compact excavator meter should be taken care of as it is a basic condition required for a machine to work at its maximum capacity and for it to have a long service life.

- Some of the safety measures taken in small excavators operations include employment of well-qualified, trained workers, use of proper individual protection equipment and strict observance of the instructions provided by the manufacturers.

- The personnel should take concerted efforts in operating the same in efficient mode and also make use of additional equipment for giving them a broader range of applications if they really want to make the best use of the time available with compact excavators.

Choosing the Right Compact Excavator for the Job

If we really want to find the best compact excavator for our job, we should go through a list of factors that are relevant to the project. The first and most important step here is to get ourselves acquainted with the project.

For instance, if the work is about digging trenches for utility lines in a community, a smaller model with less width may be more appropriate. On the contrary, heavy works that require moving a large amount of soil may need a machine with strong lifting power and a long arm to do the job.

How we weigh the heaviness of an excavator in comparison with its working area can have a double effect on safety and working efficiency. In addition, the world in which the compact excavator is supposed to work is yet another huge point that should not be neglected.

For example, if the work area is a bumpy place or made of soft soil, then wide tracks will be stable, they will also be safe because the pressure on the ground will be less.

Furthermore, the operator must have a look at the hydraulic performance of the machine, as different models have different flow rates and pressure levels that may affect performance with the use of the attachment.

It is also a good idea to consider how easily the machine can be transported; some mini excavators are designed in such a way that they can be loaded on regular trailers, and this can save time and money in transport.

Proper Maintenance and Care for Compact Excavators

It is essential to a compact excavator that people take proper care of it in order to it last longer and work at its full capacity. The user should on a daily basis check the components of the machine among which the hydraulic fluid, engine oil, and coolant should be mentioned. A check for leaks in hydraulic hoses and connections is very important, as small leaks can cause the machine to lose a large part of its performance in due time.

Moreover, the operator should look for damage in the lower support of the machine as this part is usually in close contact with the harsh conditions during work.

They should follow regularly the maintenances schedules stated in the product manuals by manufacturers. The works of changing filters, lubricating moving parts, and replacing the worn components such as tracks, and buckets are included in this.

Apart from that, keeping records of maintenance occasions is not only good for determining the state of the machine but also can help in spotting the problems that are repeating and have to be solved. Besides, buying high-quality replacement parts can both prolong the lifespan and confirm that the excavator works at its best quality.

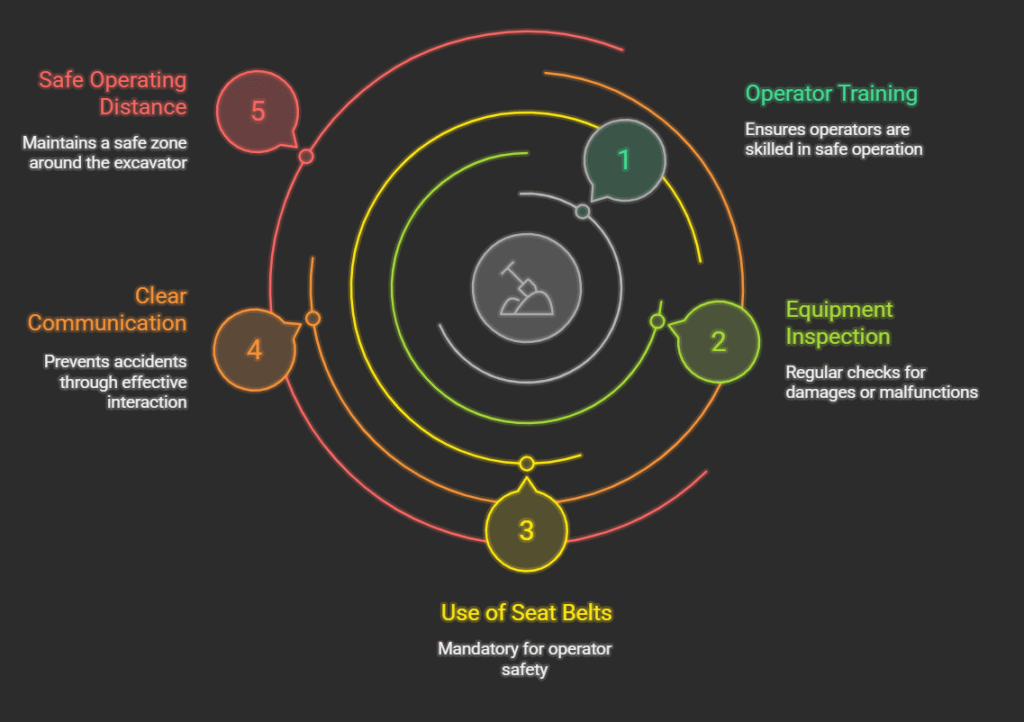

Safety Measures for Operating Compact Excavators

Safety is a major issue in the area of operating compact excavators, as the potential hazards are always lurking in the zone of heavy machinery.

Therefore, operators must be fully conversant with them to avoid any accidents at the site of work. The main safety rule is that the pre-operation inspection of the machine should be very thorough. Ensuring that all safety features are active, all controls are in a working state, finding any possible damage among the visible parts, and so on are all parts of this check.

Alongside the instruction manual, a good familiarity of the machine with safety features and guidelines is a must for the operators. The PPE, i.e. the “Personal Protective Equipment”, must be worn by all the workers in the organization in order for the safety standards to be met.

It consists of hard hats, safety glasses, gloves, and steel-toed boots for each of which protection against falling objects or malfunctions of the equipment is the potential role.

The operators must also be trained in identifying some risks like overhead power lines and unstable ground conditions. The use of a system of easy communication among the staff is beneficial in the aspect of safety as it makes sure every member is acquainted with the ongoing operations and thus, the risks.

Tips for Maximizing Productivity with Compact Excavators

One of the main strategies is to lay out the worksite and define the operations in a simple manner. Operators by organizing tasks in logical order, such as digging before grading, can save the time that otherwise they would spend in various unproductive activities and workflows are simplified.

Further, the use of GPS can lead to better results in cutting and digging, and less time is spent on the parts that have to be redone. Experience has a lot of importance in productivity and that can be simply brought by operator skills.

By training the operators for the job they will not only become more efficient but will also be able to solve some problems on the spot which in turn will save a lot of time.

Operators should first become familiar with the different kinds of attachments and then in a short time they will also be familiar with the different tasks of the compact excavator.

For instance, a material handling capacity can be dramatically increased by a hydraulic thumb attachment which can then lead to the loading and unloading processes being carried out in a much more efficient way.

Utilizing Attachments for Versatility

One of the main features compact excavators have which gives them such versatility across a job site is the ability to successfully utilize attachments.

Attaching various attachments to the standard excavator can change it from a simple digger into a multi-purpose tool with which numerous tasks can be performed without the need to do simple ones first or alone.

As an illustration, the bucket part may be removed and replaced with an auger to drill holes for fence posts or foundations, thus, the staff would be able to perform different parts of the same project without requiring multiple machines.

Other popular attachments are hydraulic breakers that are used to demolish structures, cranes for the movement of materials, and quick trenching for nicely digging the necessary depth.

Attachments of various kinds may differ in characteristics and by knowing the limitations as well as the advantages of each type of attachment, operators will be guided to select the right one depending on the need of the job.

In fact, operators also save a lot of time by knowing a very fast way to change attachments which is the reason why they can be more productive when they are working on site.

Training and Certification for Compact Excavator Operators

First of all, safe and effective use of small excavators is inseparably connected with the proper personnel training and certification. It is a requirement in several areas that all the operators must undergo certified training programs which combine theoretical knowledge and practical skills.

Among other subjects, these programs generally consist of instructions on the basic operation of the machine, health and safety, maintenance, and emergency practice.

The scope of certification goes well beyond an operator’s credentials as well as putting a stamp of the necessity of safe machinery handling on the operator’s mind.

Moreover, the hands-on part of training is simply as significant; operators under the guidance should be allowed enough time to rehearse the use of compact excavators before they start working on their own at the location of the job.

The correct way of doing this is to combine training with on-the-job practice which allows them to learn by doing while at the same time following safety protocols.

Besides that, they can likewise become conversant with different types of attachments. Apart from that, regular programs can give operators a first-hand experience of any new development in technology or professional guidance that may improve their work or safety in any way.

Advantages of Compact Excavators for Various Construction Projects

One of the main advantages of compact excavators is the fact that they can do jobs with a very wide range of construction works, which makes them very valuable in many cases.

The limited space they occupy makes it possible for them to reach places that are too small for even other small but bigger machines. Their capability in this context is, among other things, very important in cities where this kind of problem is very common.

To illustrate, if you are restoring houses or utilities in a heavily populated area, then maneuvering through tight alleyways or you can even be operating directly in the backyard using compact excavators to make the task simple and trouble-free.

Besides that, it is also important to note that due to the small engines and light bodies of compact excavators, they are usually more fuel-efficient than the bigger ones.

This ultimately results in lower operating prices over time, making them a perfect choice for the contractors aiming at the maximization of profits.

Also, the fact that they are versatile means that they can do almost any job such as gardening and landfilling, thus there will be no need to bring in additional machines, hence simplifying the process and saving time.

Overall, it would seem that the compact excavators signify a perfect combination of power and nimbleness that make them fit for various implementations in the construction and landscaping fields.

Additional to this, their multifunctionality exploits the different kinds of attachments to further increase the utility while at the same time making it possible for operators to perform a wide array of tasks in a time efficient manner. The constant improvement of technology in this field will basically result in keeping compact excavators in the lead of all kind of modern construction practices.